Dielectric antennas

All-dielectric antennas

Historically the main antennas used for wireless applications (resonant and traveling-wave) were metallic, as it was the traditional material used for conducting electricity and generating/receiving electromagnetic waves. These days, new requirements for increasing data-rate of high-frequency systems (radar, mobile communication) require higher operating frequencies in the sub-THz range and beyond. At these frequencies, the losses in the metal, which were until now mostly neglected, become much more prevalent in the form of higher resistance due to skin depth and surface roughness. A solution is thus required for new types of antennas that will allow an efficient radiation of electromagnetic waves for these systems.

A promising approach to replace metallic antennas is to use dielectric materials only. Their behaviour at high frequencies does not depend anymore on loss mechanisms based on metallic conduction but solely on dielectric properties. Historically, dielectric antennas were investigated as traveling-wave antennas such as dielectric rods, with much research later conducted on dielectric resonator antennas (DRAs).

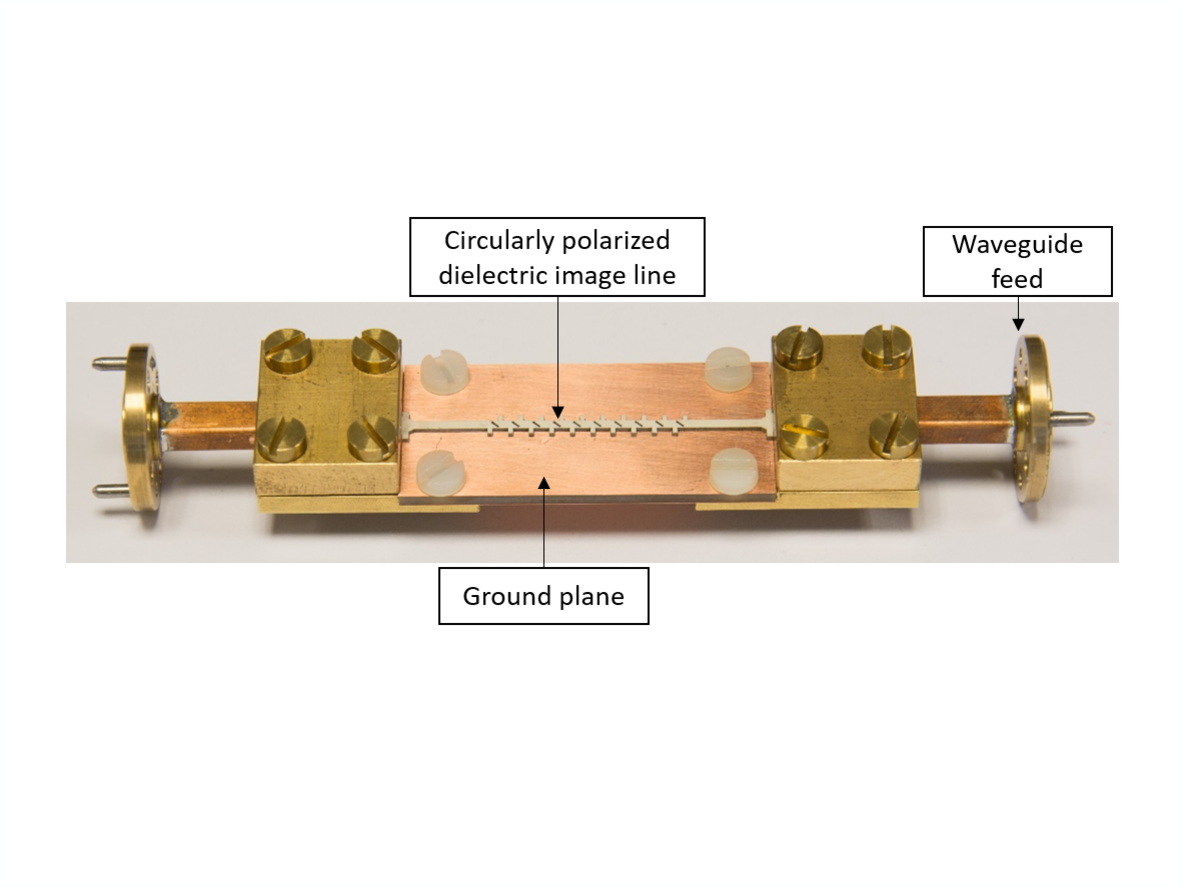

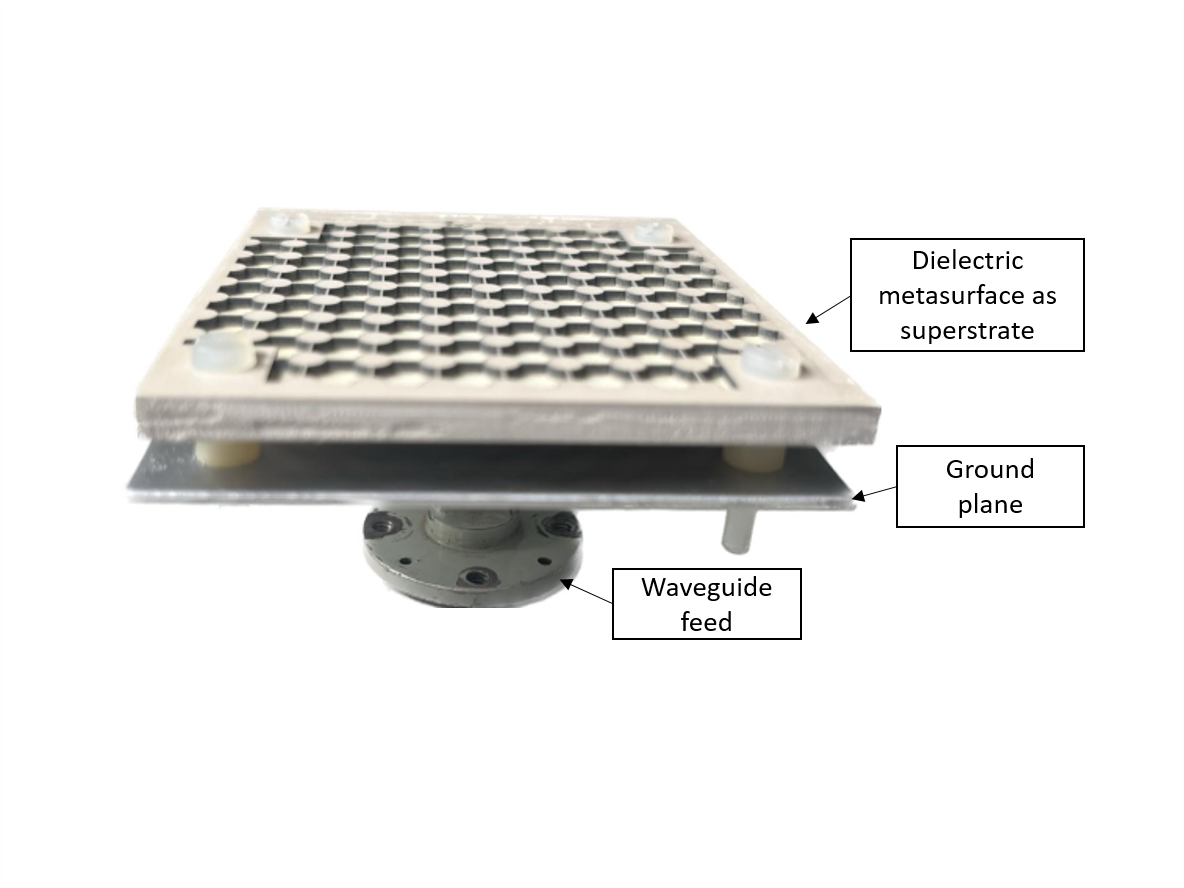

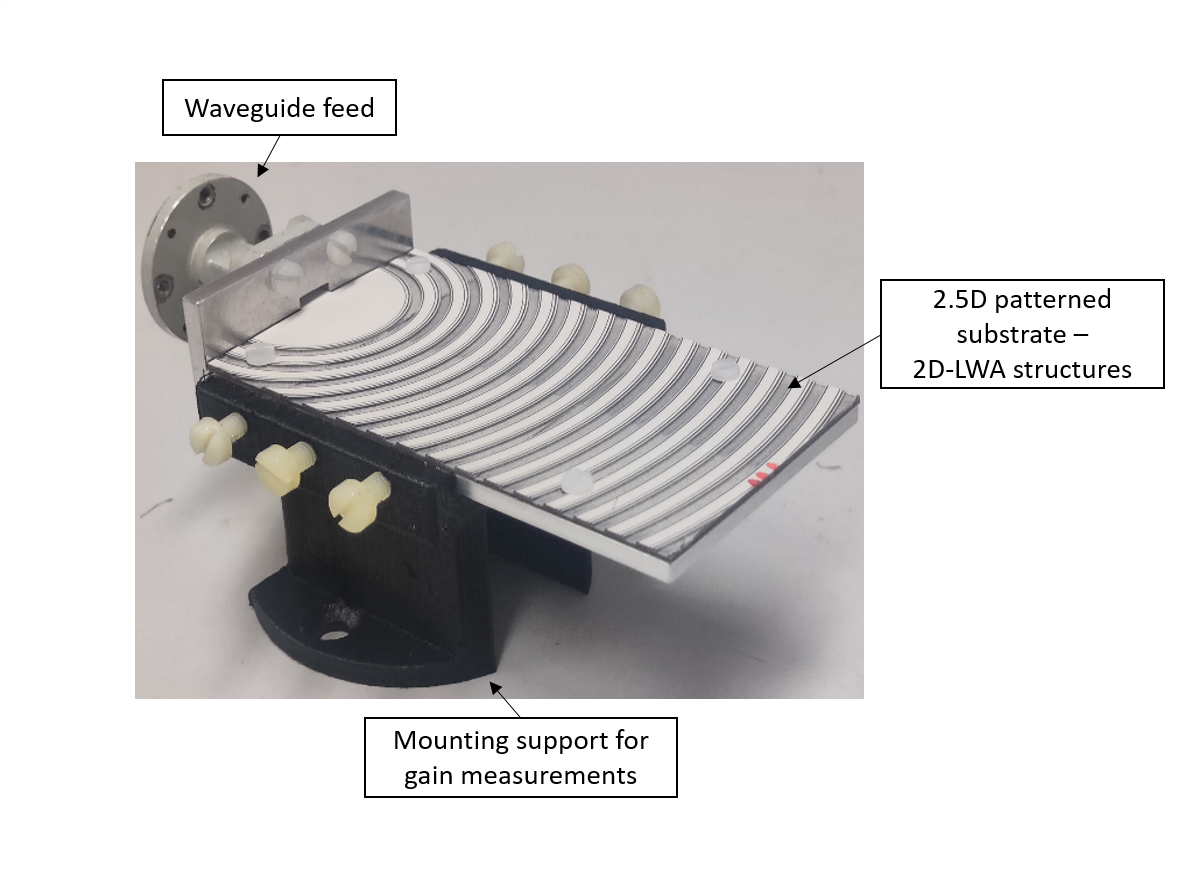

At IHF, research was focused on designing, producing and characterizing dielectric image lines (DILs) operating at 77 GHz (radar frequencies). Further research is now underway designing 2D-leaky-wave antennas (2D-LWAs) and surface wave antennas based on dielectric metasurfaces and substrates.

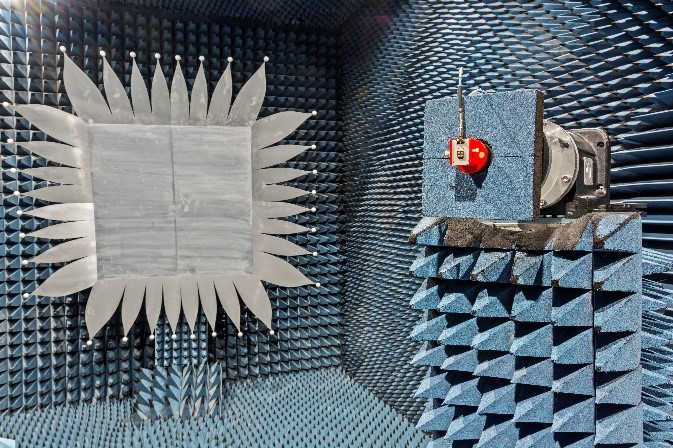

Dielectric metasurfaces

Many antennas are required to be highly directive, radiating only in one hemisphere and in a very focused way. The state of the art to achieve such a functionality is to use a metallic ground plane that will reflect waves to a desired direction. Investigations are taking place on so-called all-dielectric metasurfaces: dielectric planar structures with reflection capabilities that could replace metallic ground planes, for example those used in 2D-LWAs.

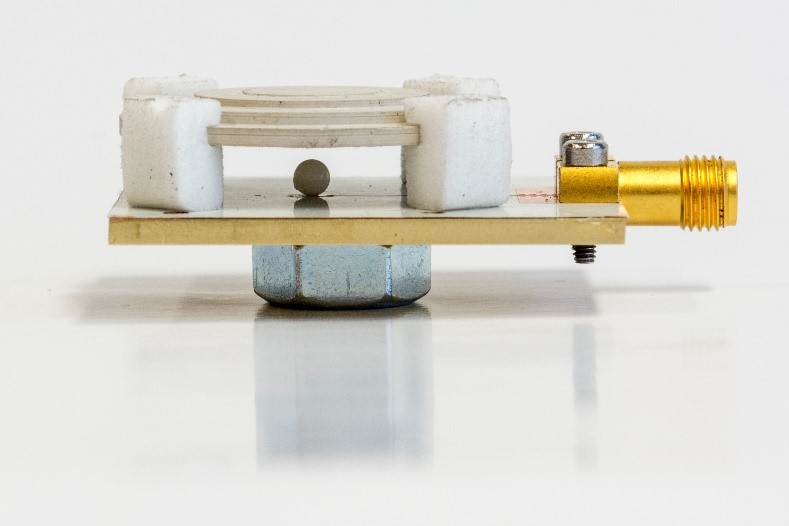

Spherical Dielectric Resonator Antenna

Many communication devices are nowadays shifting towards millimeter-wave frequency range to fulfil the ever-growing demand for higher data rates and to avoid the overcrowded lower frequency spectrum. However, the mm-wave traditional on-chip antennas based on thin substrates typically suffer from low radiation efficiency, high conduction loss, large on-chip area requirements and low bandwidth. As a solution, transmission line-based structure in the back-end-of-line (BEOL) layer of the chip can be used to couple the antennas mounted directly on-chip. The spherical dielectric resonator antennas (DRA) come in handy as on-chip antennas since they offer precise self-aligning assembly capability, lower chip-area consumption, higher radiation efficiency and higher matching bandwidth. This proposed antenna can find its separate application by implementing it in thin low-permittivity substrates (as in this work) as well.

A quarter-wave long microstrip resonator with shorting vias to the metallic ground plane is needed to provide enough coupling to excite a variant of E101 mode of spherical dielectric resonator. A circular crate in the thin dielectric substrate at the location of the sphere eases its precise placement.

At IHF, research is being conducted to improve the radiation performance of such antennas by adopting a simple metallic wall structure and incorporating a new superstrate structure to form a resonant cavity antenna.

Fabrication

Part of the attractiveness of this research topic lies in the surge of technologies that enable the prototype production of dielectric antennas and metasurfaces. Affordable and relatively compact laser milling machines allow 2D/2.5D structuring of dielectric substrates, while 3D printing machines are now beginning to be ubiquitous with an ever-growing research on their compatibility with high-frequency applications. New high-frequency materials compatible with 3D printing are being released, which will enable a complete package for prototype production.

IHF, with the help of the Fraunhofer Institute for High Frequency Physics and Radar Techniques (FHR), has at its disposition the following equipment:

- LPKF Protolaser S

- 3D printers: Formlabs, Keyence Agilista, Anycubic